XPanelTM

X

A new Way to Add Heat Recovery Ventilation to an older building

The XPanel™ is a custom designed HRV manufactured using TCPoly’s proprietary materials and 3D printing process. It is proof that a product can be 3D printed with Ice9 filament and compete with traditionally manufactured products. The energy exchange panels can recover the energy from the building’s exhaust air stream without any moving parts or complicated maintenance schedules.

The pilot installation is on track for a 3-year ROI.

Centergy One Building

XPanel™ Pilot Installation

The Centergy One Building in Midtown, Atlanta is located within Georgia Tech’s Technology Square and contains offices, restaurants, and a fitness center. The installation went live July 2022.

This pilot installation shows the performance of our XPanel™ and how a system can be retrofitted to buildings that do not currently have a ventilation recovery system with 3D printed parts made of Ice9 filament.

XPanelTM

The XPanel™ is a high efficiency energy recovery ventilation product. The advanced heat and moisture recovery system can reduce heating, cooling, and ventilation costs without incurring negative economic or equipment impacts.

Materials Innovation Meets Advanced Manufacturing

TCPoly created the world’s highest thermal conductivity 3D printing plastic (>50x higher than standard plastics) with the ability to transfer both heat and moisture at high efficiencies. Our materials essentially have all the advantages of standard plastics (such as corrosion resistance, light weight, low cost, long service life, ease of manufacturing), but the unique ability to conduct heat like a metal. Moreover, our filaments can be used in low cost, energy efficient FDM printing systems to create high performance geometries not possible with traditional manufacturing methods.

Advanced Plastics With Unique Heat Conducting Properties

The Design Freedom of 3D Printed Heat Exchangers

XPanel™ - The World's Highest Efficiency Energy Recovery Panel

Energy Recovery Heat Exchangers - The Perfect Application

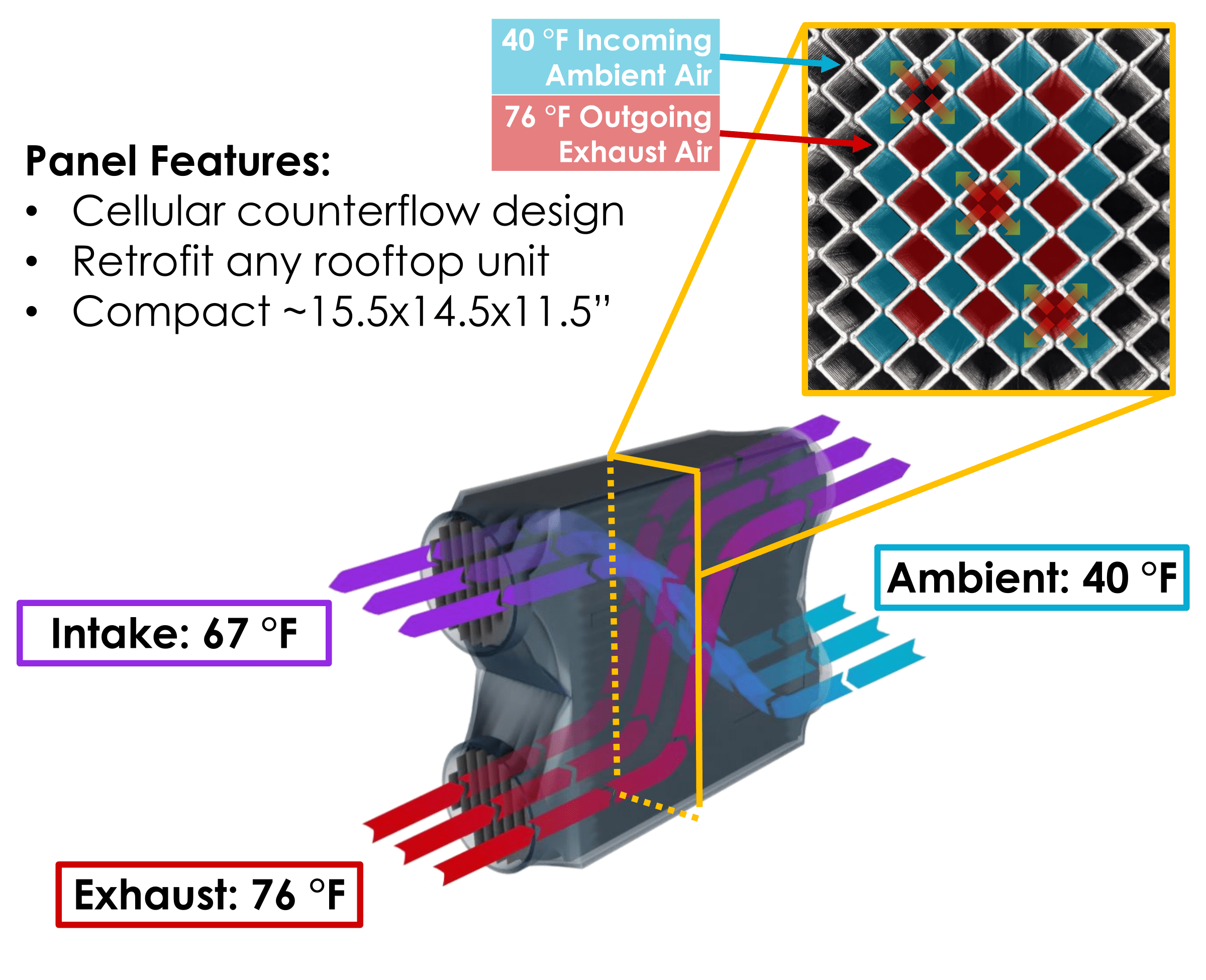

By combining our advanced materials with advanced manufacturing strategies we are able to make high performance energy recovery heat exchangers with unmatched performance. As illustrated here, our materials can transfer both heat and moisture between airstreams without cross-contamination between the streams. The heat and moisture moves across the 3D printed wall enabling pre-conditioning of the incoming supply air stream.

The XPanel™ - A New Approach to Energy Recovery Ventilation

We are excited to launch the TCPoly XPanel™ for energy recovery and harvesting in air conditioning systems. Our unique energy recovery ventilation system enables high efficiency heat and moisture transfer between the buildings in-take and exhaust airstreams, providing our customers with clean air and energy savings. The design freedom of 3D printing enables us to create customized retrofit or new energy recovery systems that work for the building configurations and can scale to any building size.

See How Our Revolutionary XPanels™ Work

XPanelTM

Simple, Low-Cost & Non-Invasive

TCPoly has developed a proprietary design that enables high performance in a light weight and easy to scale form factor. The XPanel™ is easily ducted into existing HVAC systems or can be integrated into new installations. We simply connect our panel arrays to the in-take and exhaust of standard air handling units and mount the panels on top of the duct work. This non-invasive and lost-cost installation reduces the risk for building owners as we do not alter their air handling units and the systems can be detached at any time. Our team of technical experts can size the panels to be sure that your return on investment is maximized and your system performs as expected.