Applications

Applications

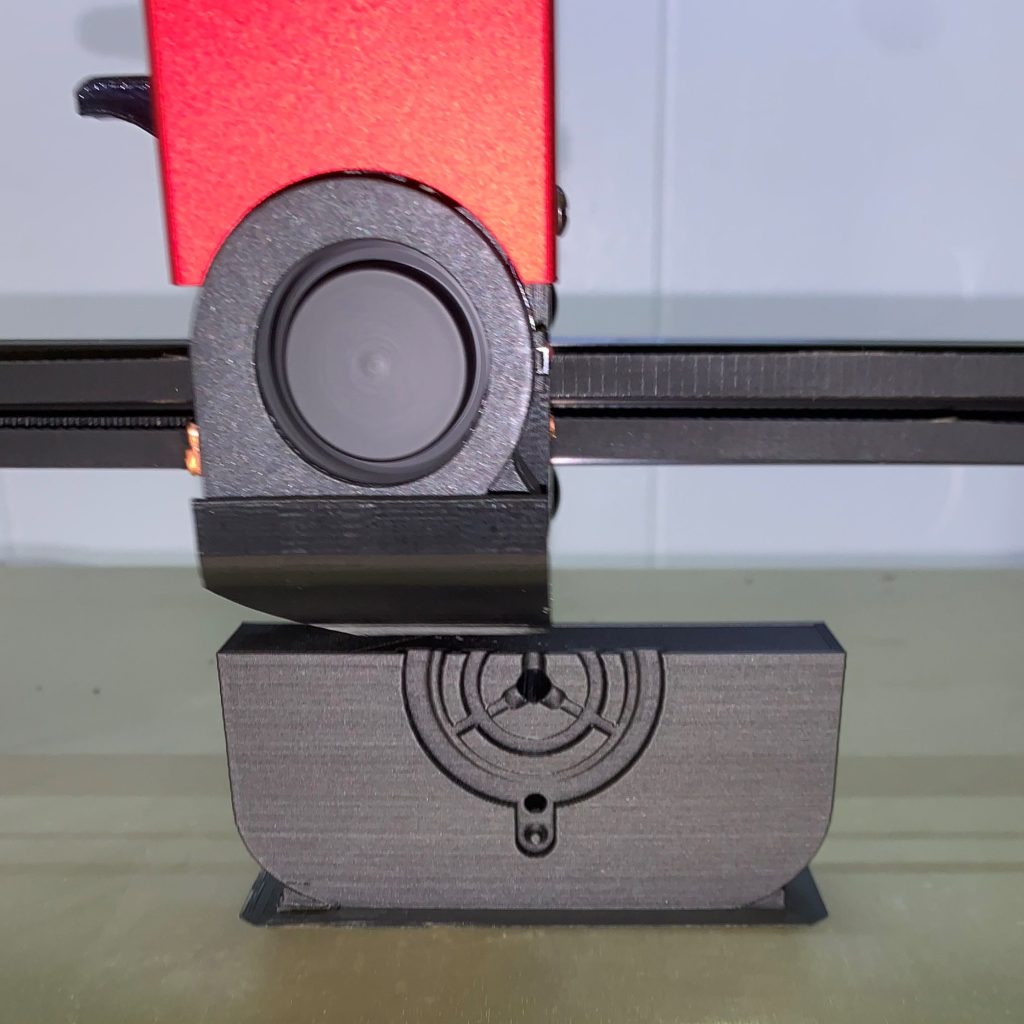

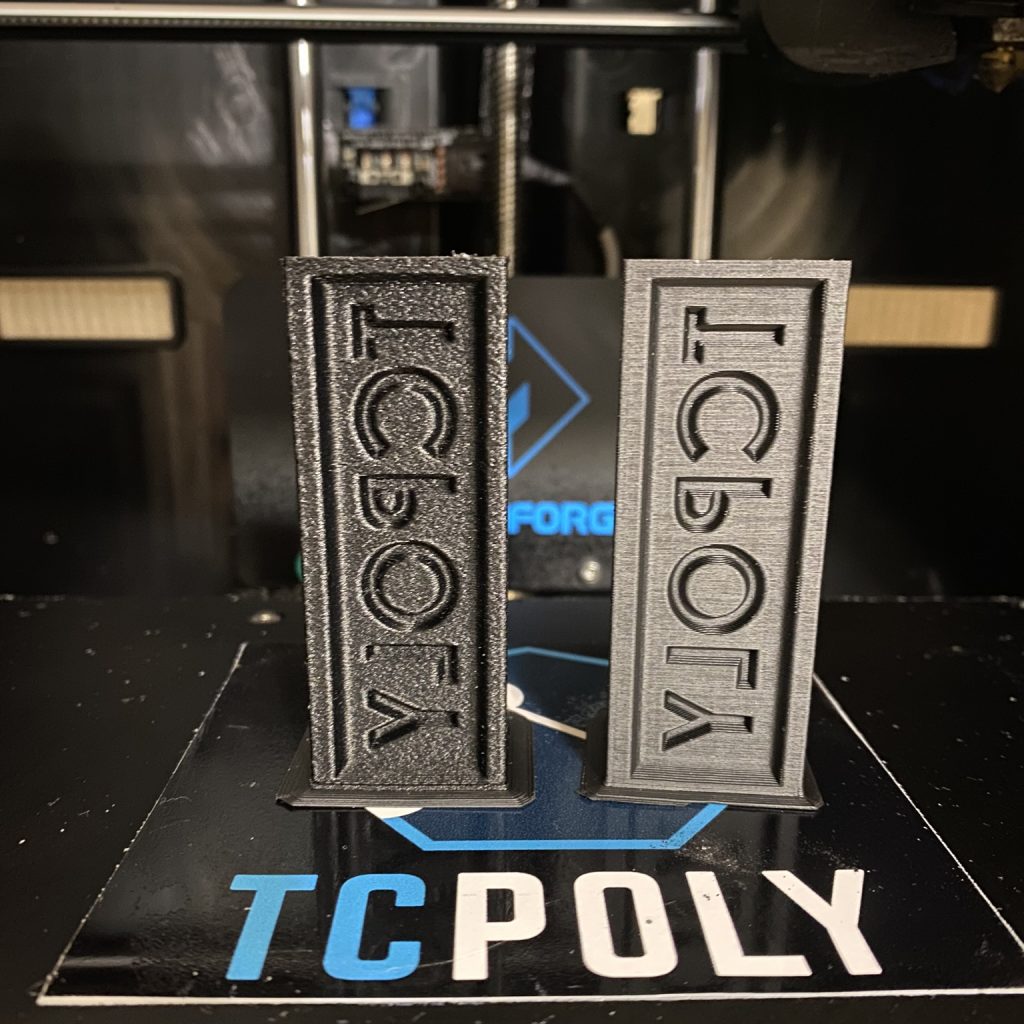

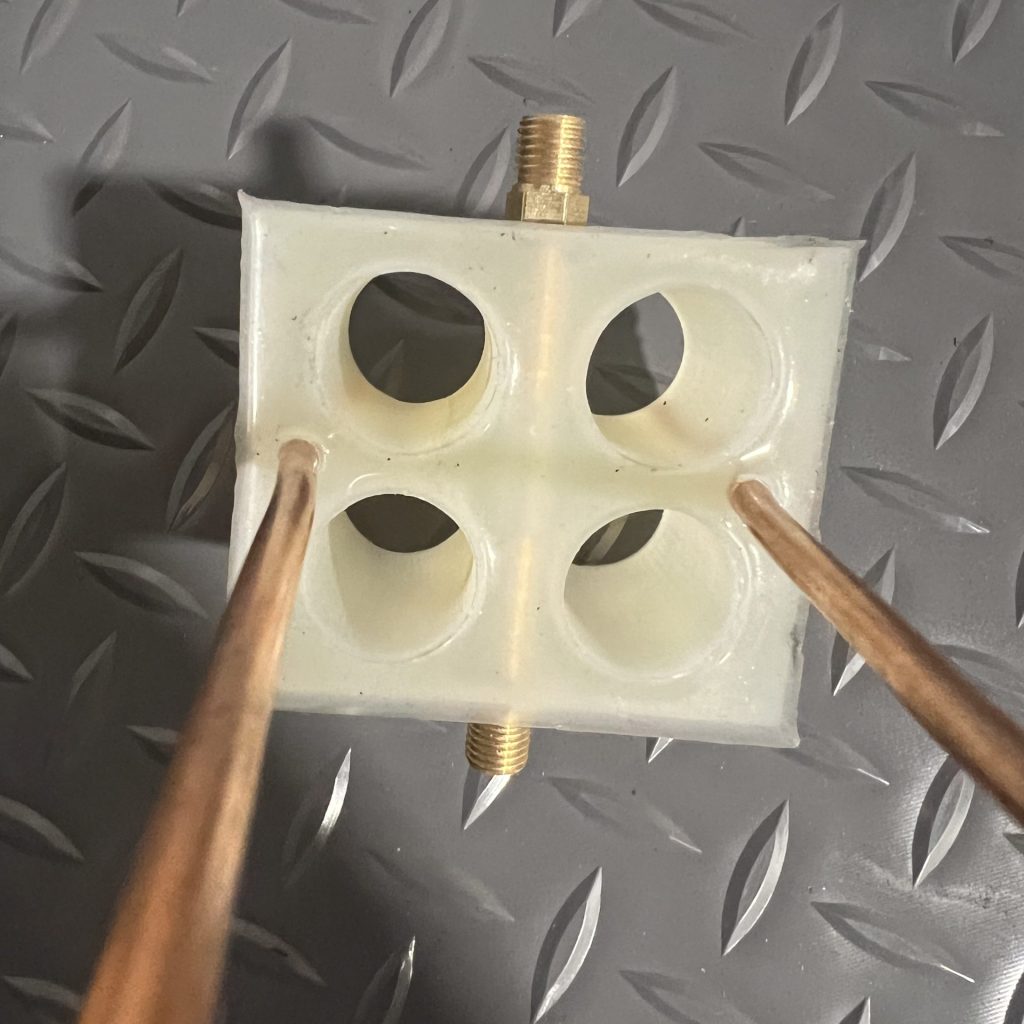

Heat Dissipating Molds

About

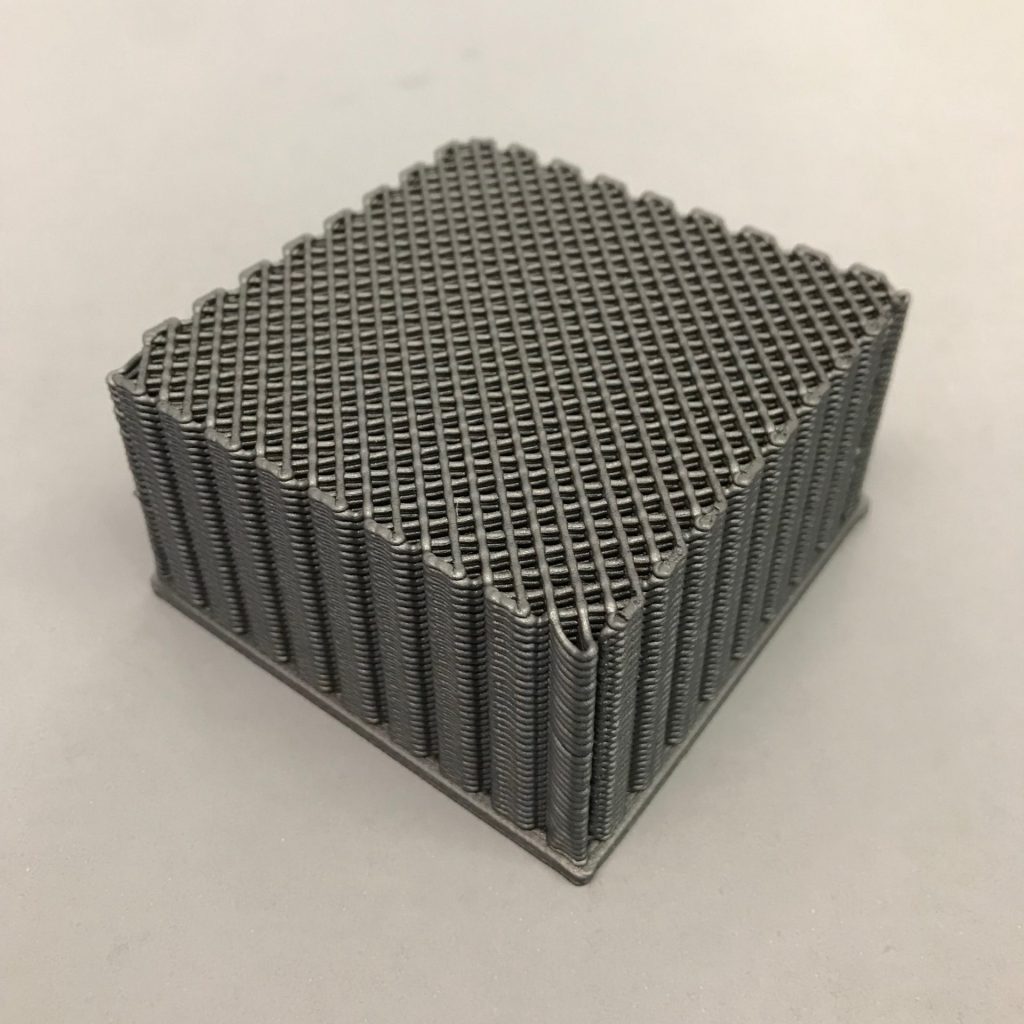

Thermally conductive polymers can be used to print molds that heat up and cool down quickly enabling fast cycle times, long tool life, and improved part quality. Inadequate heat dissipation can lead to excessive temperatures in the mold cavity, resulting in part quality issues, increased scrap, and reduced productivity. TCPoly’s thermally conductive polymers provide the thermal benefits of metals, but can be quickly printed on low-cost filament fed 3D printers and easily recycled without expensive or energy intensive processes.

Comparisons and Advantages

Ice9 thermally conductive molds are lighter and faster to produce than metal with higher performance than traditional plastics. Molds can be fabricated on low-cost 3D printers with integrated cooling channels and controlled porosity for gas/steam release. Our partners can vapor smooth and/or post machined the molds to increase strength and eliminate layer lines. Overall, Ice9 filaments enable low-cost, short lead time, and high quality molds.

Performance Molds for Injection, Thermoforming and Lost Foam Molding

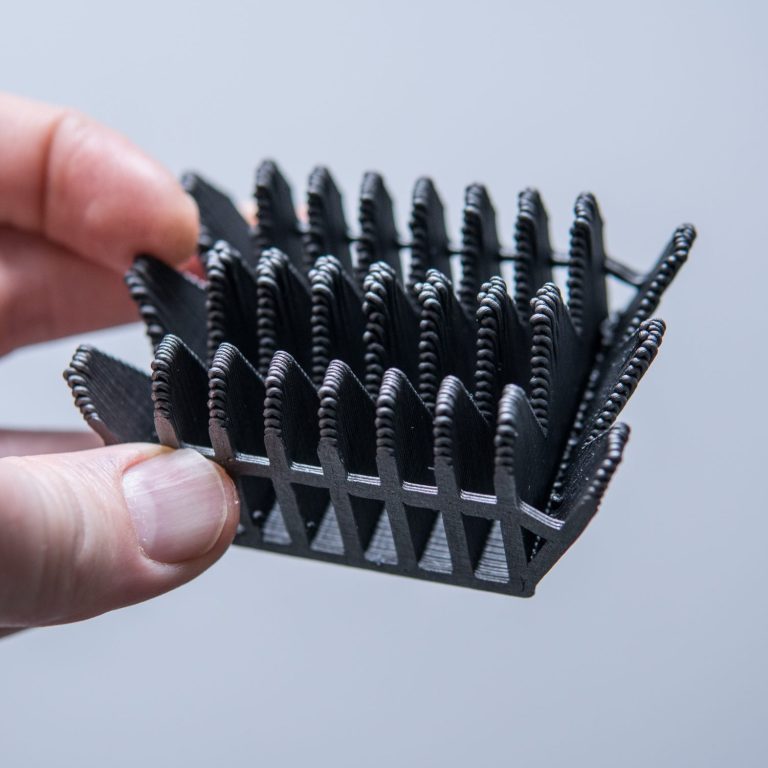

Heat Sinks

About

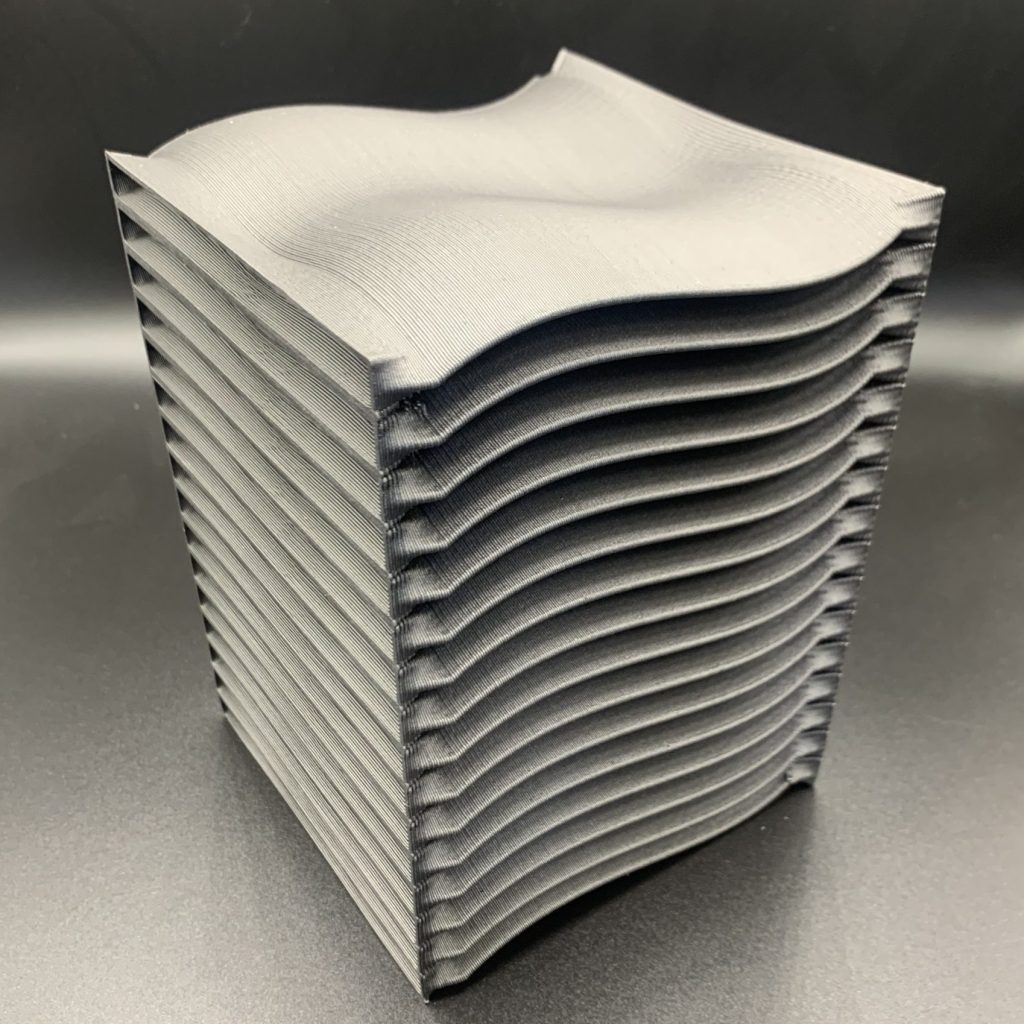

Heat sinks are passive heat transfer devices that are widely used to dissipate thermal energy from electronic components and other heat-generating systems. They work by increasing the surface area available for heat transfer, allowing the heat to be more efficiently dissipated to the surrounding air or a liquid coolant. Common heat sink materials include aluminum and copper due to their high thermal conductivity, which allows them to effectively draw heat away from the heat source. However, these materials have drawbacks including their weight, susceptibility to corrosion, electrical conductance, cost, limited design freedom, and mechanical rigidity.

Comparisons and Advantages

Quickly create custom heat sinks that incorporate unique geometry that is impossible to make with traditional manufacturing. TCPoly’s thermally conductive filaments and pellets enable the key advantages of design freedom to create complex geometries optimized for heat transfer, combined with lighter weight, corrosion resistance, and potential cost savings through additive manufacturing processes. The design and placement of heat sinks is critical to their performance, with factors like fin geometry, surface area, and airflow patterns all playing a role in optimizing their thermal management capabilities.

Light weight, Electrically Insulating, High Performance Heat Sinks

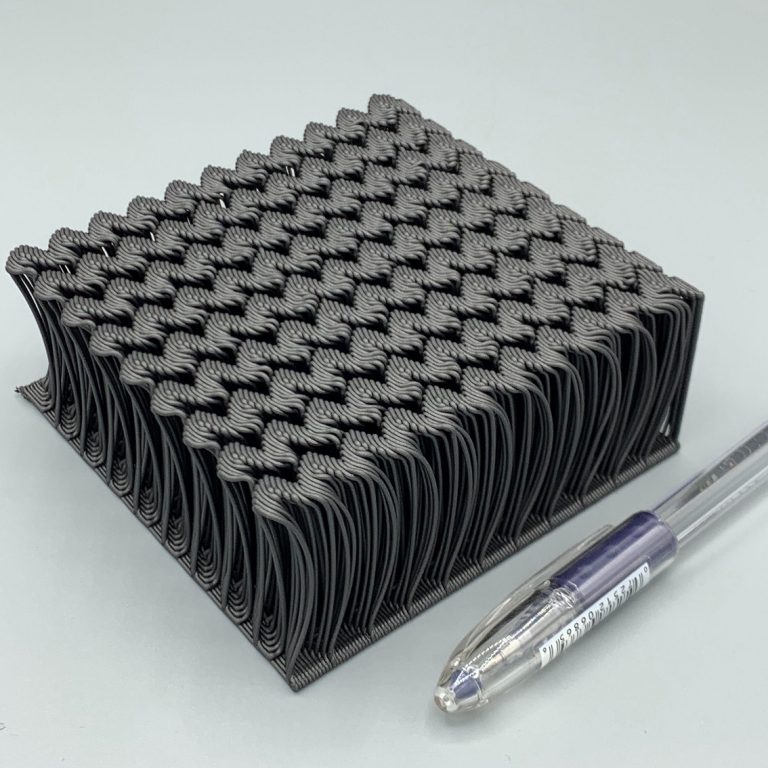

Heat Exchangers

About

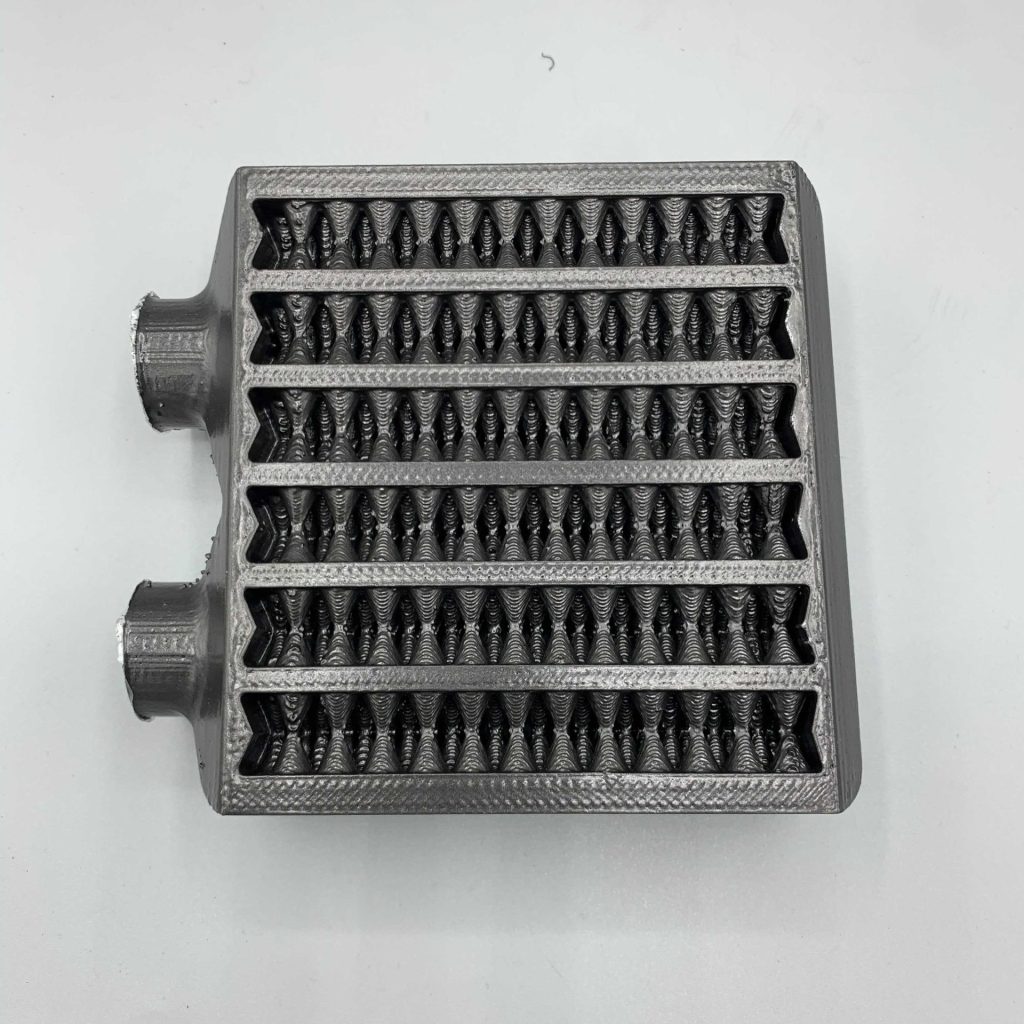

Thermally conductive polymer-based heat exchangers leverage the design freedom of additive manufacturing to create complex internal geometries that optimize fluid flow and heat transfer characteristics. Polymer heat exchangers provide benefits such as reduced weight, corrosion resistance, and lower manufacturing costs compared to metal counterparts. They have found use in applications ranging from microelectronics cooling and water desalination to solar water heating and liquid desiccant cooling systems. The design flexibility and thermal performance of these polymer-based heat exchangers make them a promising technology for improving energy efficiency and enabling new thermal management solutions across industries.

Comparisons and Advantages

3D printing allows for the creation of intricate internal structures and shapes that are extremely difficult or impossible with conventional manufacturing methods. This enables optimizing fluid flow paths, surface areas, and heat transfer characteristics to boost performance. Thermally conductive Ice9 materials have a lower density than metals, enabling lightweight yet effective heat exchanger designs, especially when using lattice structures and novel geometries. Moreover, our materials are corrosion-resistant, making them suitable for harsh environments where metals may degrade. Finally, 3D printing enables on-demand, distributed manufacturing with minimal waste, potentially reducing costs compared to machining metal heat exchangers.

High Performance 3D Printed Heat Exchangers

Battery Packs

About

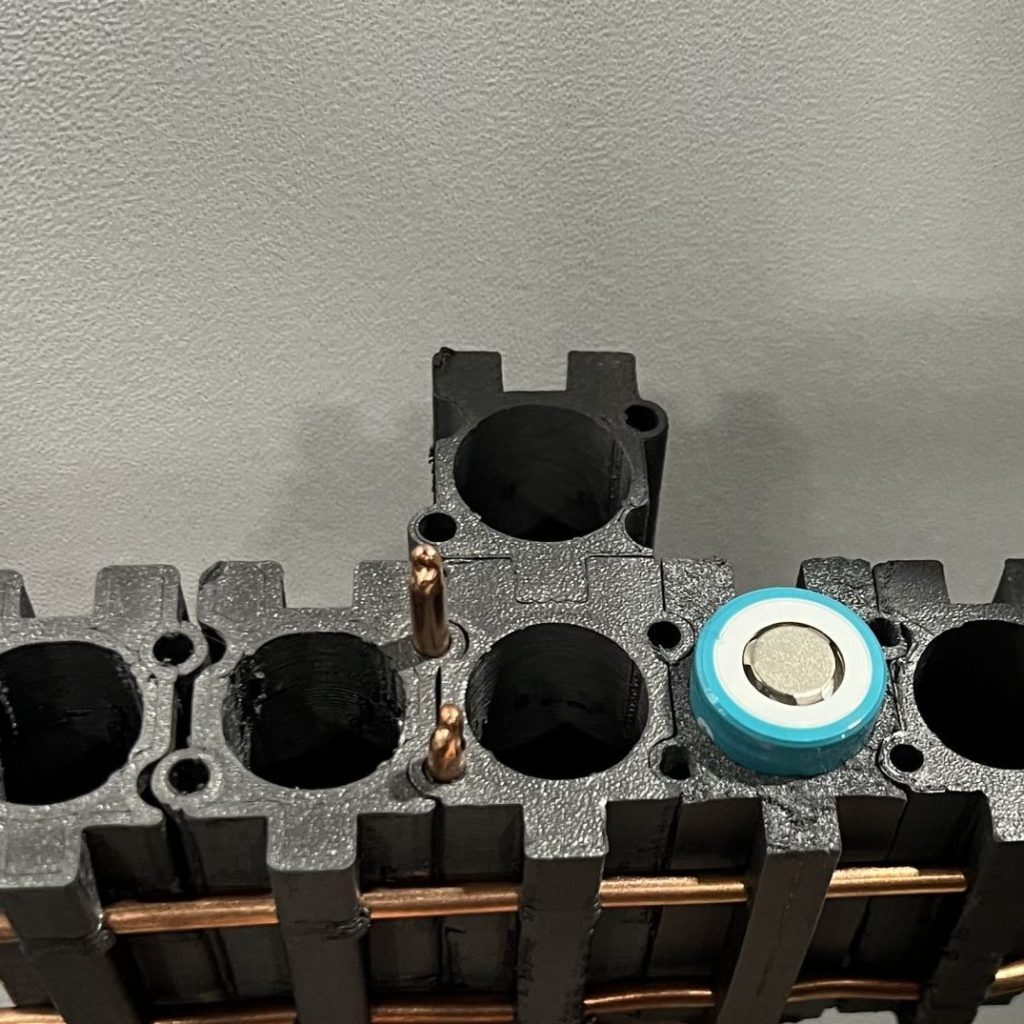

Effective thermal management is critical for ensuring the safe and reliable operation of battery packs, particularly in high-power applications like electric vehicles and energy storage systems. Overheating can lead to reduced battery life, performance degradation, and in extreme cases, thermal runaway and fire hazards. Heat sinks, cold plates, and other cooling solutions are often integrated into battery pack designs to actively remove heat generated during charging and discharging. The choice of cooling method – air, liquid, or phase change materials – depends on factors like the power density, operating environment, and packaging constraints.

Comparisons and Advantages

The use of thermally conductive polymers can provide significant advantages for cooling battery packs. These thermally enhanced packs enable more efficient heat transfer away from the battery cells compared to standard insulating enclosures. The improved thermal conductivity allows for more uniform temperature distribution across the battery pack, which helps maintain optimal operating conditions and prevent hotspots that can lead to performance degradation or safety issues. The design flexibility of 3D printed thermally conductive polymer cases also allows for the integration of complex internal geometries that enable optimized airflow or liquid cooling channels. Additionally, the lightweight and corrosion-resistant properties offer benefits in terms of reduced weight and improved durability compared to traditional metal enclosures

High Performance 3D Printed Battery Packs

Enclosures and Cases

About

Enclosures and cases are widely used to house and protect a variety of electronic devices, appliances, and industrial equipment. Plastic enclosures and housings provide a lightweight, durable, and cost-effective solution for shielding sensitive components from environmental factors like dust, moisture, and impact. Plastic materials offer design flexibility, allowing for the creation of complex geometries and integrated features that can enhance functionality, ergonomics, and aesthetics. One primary challenge with using standard plastics, however, is that they insulate the devices and drive up device temperature.

Comparisons and Advantages

Thermally enhanced cases and enclosures enable more efficient heat transfer away from heat-generating components, helping to maintain optimal operating temperatures and prevent performance degradation or failure. The design flexibility of 3D printed or molded thermally conductive polymer enclosures also allows for the integration of complex internal features like cooling channels to further enhance heat dissipation. Thermally conductive polymer cases offer weight savings over metal enclosures, which is particularly advantageous for portable electronics and transportation applications. Additionally, the corrosion resistance of many thermally enhanced polymers can improve the durability and reliability of the electronics system in harsh environments.

Thermally Conductive Cases and Enclosures